Selecting the right blast-resistant building can be overwhelming and requires more than a general understanding of safety. Because blast-resistant structures play a vital role in protecting personnel and preserving operations in high-risk environments, every design and material decision is critical.

Yet despite the importance of accurate and transparent blast-resistant building information, misconceptions still influence the evaluation of blast-resistant buildings. Incomplete or inaccurate assumptions about cost, design, or functionality can lead to choices that compromise safety, inflate budgets, or reduce long-term value.

RedGuard has helped clients across industries, like petrochemical and renewable energy, navigate these complexities with tested solutions and transparent guidance. By breaking down common myths and replacing them with engineering insight and real-world data, we aim to give you the confidence to choose the optimal blast-resistant design for your needs.

Concrete has long been regarded as a standard material for structural strength and permanence. In traditional construction, that reputation is well earned due to its weight-bearing abilities, but blast-resistant buildings are not traditional structures.

When concrete is subjected to the intense, rapid pressure of an explosion, it behaves differently. It can crack, fracture, and chip, sending sharp fragments into the building interior. Fragments create secondary hazards that can cause serious injury or damage, even if the structure itself remains standing.

By comparison, steel offers distinct advantages in both performance and protection. Steel is known for its strength, resilience, and reliability in dynamic environments. Unlike concrete, steel does not crumble or shatter under blast pressure. Instead, it maintains its integrity, even in extreme conditions.

Steel also provides a critical safety feature: flexibility. It can bend in response to a blast wave — a behavior known as deflection or dynamic load transfer. This allows the structure to absorb and redistribute energy rather than resist it all at once. That ability to “flex” significantly reduces the likelihood of structural failure and helps prevent internal fragmentation, keeping occupants safe and minimizing equipment damage.

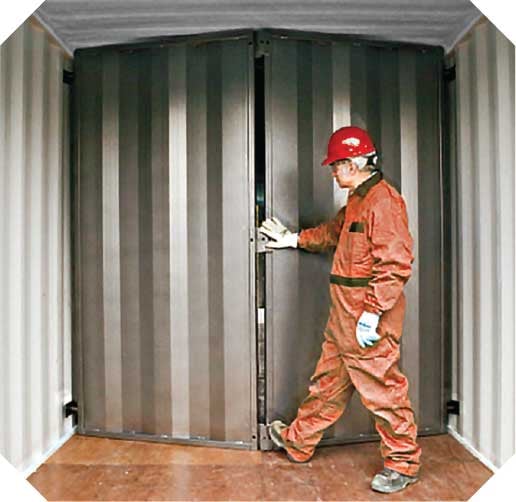

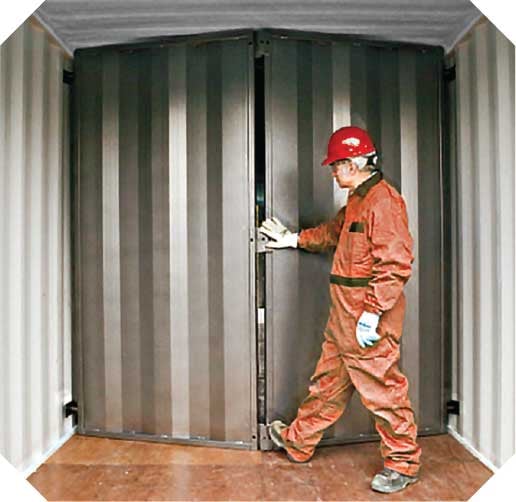

We have conducted extensive live blast tests to validate the performance of RedGuard’s steel structures under various explosive forces. Our steel units have not only remained structurally sound in blast simulations, but they’ve also demonstrated superior performance in limiting debris and internal damage.

Photos and reports from these blast tests show how steel walls deflect under stress without failing, protecting building occupants and preserving functionality.

In high-risk sectors like energy and defense, the material you choose has implications far beyond the build site and can directly impact what happens in a worst-case scenario. Steel gives us the ability to design buildings that are strong, adaptable, and above all, safer for those inside.

It’s a common misconception that blast-resistant buildings are cold, utilitarian boxes with little regard for appearance or occupant comfort. While this may have been true of early models, modern blast-resistant buildings are far more adaptable and far more refined.

Today’s blast-resistant units can be fully customized to match the operational and environmental needs of a facility, from layout and lighting to insulation and air quality. No matter the space’s use or size, we can help make sure it feels safe, functional, and professional, not temporary or makeshift.

RedGuard steel blast-resistant buildings offer customization options, including:

A common concern among facility planners and operations teams is that adding a blast-resistant building will lead to lengthy site disruptions, tie up critical resources, or interfere with day-to-day operations. That concern often stems from outdated expectations based on traditional construction methods, particularly concrete builds, which do require significant installation time and labor.

With steel blast-resistant buildings, the timeline and building process are fundamentally different.

Steel blast-resistant buildings are fabricated off-site in a controlled environment. This means that quality is maintained from start to finish, regardless of weather conditions, labor shortages, or other variables that typically delay construction projects. When the building arrives on-site, it’s already been assembled, tested, and then disassembled for transport. It is ready for installation with minimal additional work required.

Many steel blast-resistant buildings can be fully installed and operational within 1 to 4 weeks, depending on size and complexity. Installation includes placement, utility tie-ins, and connection of the disassembled pieces. In comparison, concrete construction can require a much longer timeline, more workers, and an installation process that resembles an entire build rather than an assembly.

We also work closely with clients in advance to handle site planning, permitting, and logistics, so your team knows what to expect and when. Ultimately, blast protection shouldn't come at the cost of extended downtime. With steel construction, your facility stays operational, your people stay safe, and your schedule stays on track. Connect with us to learn more about the installation process timeline for your specific needs.

There’s a persistent belief that blast-resistant buildings are only practical for small projects and that once you need more space, complexity increases and options become limited. In reality, large blast-resistant buildings do require careful design, but RedGuard makes it easy, thanks to advances in modular design and engineering.

Whether it's a single-unit structure or a fully connected multi-room facility, modular steel construction enables safe and efficient expansion without the complexity and delays often associated with large, conventional building methods.

Our multi-section blast-resistant buildings are constructed using 12-foot-wide modules that can be joined and configured into layouts up to 24 feet wide and beyond, with custom interior walls, doorways, and floor plans tailored to your operational needs. This flexibility allows us to create everything from open-concept workspaces to segmented office suites, control centers, or even locker rooms, all while meeting API 752 and API 753 standards, and meeting the criteria for a low or medium response rating by the American Society of Civil Engineers.

As facilities grow or evolve, space requirements change, but safety requirements don’t. RedGuard’s scalable steel designs allow you to expand without compromising protection, so your team has the room to operate efficiently while maintaining the blast resistance necessary for high-risk environments.

It’s a common misconception that steel blast-resistant buildings are best suited for temporary or short-term applications. In truth, RedGuard’s steel buildings are engineered to last and to do so in some of the harshest industrial environments imaginable.

RedGuard has two lines of blast-resistant buildings, our SafetySuite line, completely custom and engineered for long-term siting, and LeaseFleet, for temporary or shorter-term needs. Both are designed with heavy-gauge steel, reinforced framing, and secure foundation anchoring to offer durability and security for decades.

Steel is inherently well-suited for blast-resistant construction, thanks to its strength, durability, and resistance to environmental wear. Steel is extremely durable on its own, and when paired with proper reinforcement and protective coatings, can endure prolonged exposure to moisture, extreme temperatures, and corrosive industrial conditions. Unlike materials that deteriorate, crack, or are susceptible to rot, steel retains its structural integrity, making it a reliable choice for long-term safety in demanding environments.

Steel also offers a key advantage in maintainability. Since its structure is exposed, it’s easier to inspect and far less likely to experience hidden damage. Steel can be easily adapted to meet changing compliance standards or desired modifications, simplifying long-term adjustments.

Our buildings are designed to stay in place for decades, serving as control rooms, break spaces, or secure operational hubs. And when your needs shift, they can be relocated or reconfigured with minimal disruption. Modular steel blast-resistant buildings can be both temporary solutions or long-term protection because they’re backed by structural reliability, material resilience, and proven performance in the field.

Steel is long-lasting and leaves a minimal environmental footprint compared to concrete or other materials.

It’s a common assumption that blast-resistant buildings are useful for protection, but too expensive to be considered a financially sound investment. In reality, steel blast-resistant units offer substantial cost advantages when viewed through the lens of total value over time.

The initial savings begin with construction. Because steel blast-resistant buildings can be installed with minimal on-site labor, they eliminate many of the expenses tied to extended construction schedules and site preparation. The result is a more efficient process that reduces labor costs, shortens installation timelines, and limits operational disruption — all of which contribute to a lower upfront investment.

The long-term value of steel is equally important. Because steel structures are less susceptible to cracking or permanent damage after a blast event, they lower maintenance costs and allow for quicker inspections and repairs. In contrast, rigid materials like concrete can develop internal failures that are costly and time-consuming to address.

In many cases, the added safety and resilience of a properly engineered blast-resistant building can also lead to lower insurance premiums. By mitigating risk and demonstrating a commitment to worker and asset protection, companies may benefit from reduced liability and property insurance rates, adding another layer of financial return on the investment.

When you consider construction efficiency, lifecycle durability, and potential insurance savings, blast-resistant buildings made with steel are not just a protective measure, they’re a strategic financial decision.

There’s a common misconception that to be effective, a blast-resistant building must also be designed to withstand multiple other types of threats, from fire to chemical leaks to extreme weather. While multi-hazard protection may be necessary in some environments, it’s not a one-size-fits-all requirement.

In reality, the most effective and efficient blast-resistant buildings are designed around the specific hazards of a given site. At RedGuard, we call this our precision hazard approach. Instead of overbuilding or including unnecessary features, the structure is tailored to address the actual risks present in the environment where it will be deployed. RedGuard’s steel blast-resistant buildings begin with a protection level of up to 15psi, and we add additional protections as needed.

For example, a facility located near flammable chemicals may benefit from enhanced intumescent coatings, while one with the possibility of toxic gas might require pressurization systems. Meanwhile, a building located outside high-risk zones may only require minimal blast protection, without the added cost of extra protection options. Contact our team to learn more about our multi-hazard approach to blast-resistant construction.

Hazard levels are determined through structured evaluations like Facility Siting Studies or Quantitative Risk Assessments (QRAs), which analyze the types of threats a facility may face, such as explosions, fire, or toxic releases.

These studies consider both the severity of potential incidents and, in the case of QRAs, the statistical likelihood of those events occurring. Data gathered helps identify where protection is needed, what kind of response level is appropriate (per standards like API 752/753), and how best to tailor the building’s design to the actual risks present on-site. When blast-resistant buildings are engineered to match your actual risk profile, they offer both targeted safety and long-term cost efficiency.

Designing every blast-resistant building to withstand all possible threats might sound like a safe bet, but it can lead to overbuilding, overspending, and unnecessary complexity.

A precision hazard approach focuses protection where it’s actually needed, based on the risks identified in detailed site studies like Facility Siting Studies or QRAs.

Key benefits:

While accuracy is essential in execution, inaccuracy in bid quoting and early planning can derail your blast-resistant project. A well-developed quote establishes costs, sets expectations, and aligns teams. An accurate quote makes sure that everything from materials to scheduling is planned with clarity from day one.

At RedGuard, we’ve invested in cloud-based construction-specific estimation software to guarantee our proposals are comprehensive and detailed and that we understand your needs from the start. Sophisticated software and working closely with our production team allows us to account for every aspect of a project from scope and materials to scheduling and customization.

While some companies still rely on spreadsheets to generate estimates, that approach increases the risk of scope gaps, outdated pricing, or overlooked production needs. Early inaccuracies often lead to unexpected change orders or misaligned expectations once a project is underway. Our goal is to eliminate those surprises before they happen, so what’s delivered is exactly what was planned.

In high-risk industries, time is money and safety. Delays in delivering a blast-resistant building can disrupt operations, leave teams unprotected, or delay compliance with internal safety goals. By planning thoroughly from the start, we help ensure on-time delivery and smoother installation, with fewer interruptions to your site or schedule.

Installation may be the most visible milestone in a blast-resistant building project, but it’s not the finish line. In reality, what happens down the road can still impact the success of your blast-resistant building.

Blast-resistant buildings are critical assets in high-risk environments, but effectiveness can vary over time. Over time, your operational needs may change, regulations may be updated, or the building may need to be serviced, relocated, or reconfigured. Without expert support, these updates can become challenging or even compromise the building’s protective function.

That’s why ongoing service matters. RedGuard offers on-site blast-resistant building service and continued support throughout the full lifecycle of every blast-resistant building we design, and even on those we didn’t design. From assisting with modular reconfigurations and relocations to reviewing structural integrity after a blast event, our team remains available long after installation. We also maintain detailed records for every building we deliver, including specifications, drawings, and materials to ensure any future changes are handled with accuracy and efficiency.

We believe that safety begins with clear, accurate information. We seek to share practical knowledge and help you make informed decisions about protecting people and property in your high-risk environment.

Since 1998, we’ve been at the forefront of blast-resistant steel building design, partnering with companies across industries to deliver solutions that meet the highest standards of performance and reliability. Our team brings deep experience in engineering, fabrication, installation, and ongoing support, with every building backed by rigorous testing, real-world insight, and a commitment to doing the job right.

We know that no two sites or projects are alike. That’s why we offer a range of options like standard temporary, pre-engineered, and completely customized steel blast-resistant designs. Whether you’re looking for a single-unit structure or a multi-module building, we’ll work with you to develop a solution that prioritizes both safety and operational fit.

Choosing a blast-resistant building is a safety decision as much as a purchase, and we’re here to help you make it with confidence. Connect with our team or request a quote to learn more about our blast-resistant building options.

Your safety partner in threat mitigation for hazardous areas, providing safe spaces through customizable, scalable, modular buildings. The industry leader in blast-resistant buildings.