The demand for renewable energy is on the rise, and specialty modular buildings have become a vital component in this industry. These specialty modular buildings play a crucial role in safeguarding facilities and workers from potential hazards and delivering speed and value to plants. As the renewable energy industry continues to grow, the importance of these buildings will only increase.

Unfortunately, accidents and injuries on-site are not always avoidable, especially when factors such as vapor cloud explosions, fires, lightning strikes, or spontaneous combustion pose risks. However, preventative measures can be taken to reduce the risk of accidents and limit the extent of site damage, human injuries, and exposure.

To help mitigate these risks, we will provide an overview of each renewable energy facility type and explain its potential hazards. Additionally, we will explore the significance of steel blast-resistant buildings and/or other modular buildings and why they are necessary to protect people and property and support operations within the renewable energy industry.

While the industry is still relatively new, it is growing fast. Companies are signing long-term contracts, gaining priority access to the grid, and continuing to build new plants. However, this rapid growth means that policy hasn’t entirely caught up, and safety standards and protocols are still being designed.

The energy industry need only look to incidents like the 2005 oil refinery explosion in Texas City as an example of why safety is a priority. The worst industrial accident in nearly two decades killed 15 people and injured 170 due to "organizational and safety deficiencies" and called for increased OSHA inspections, especially in light of company mergers, reorganizations, and budget cuts.

The energy industry has hazard protocols related to pressure, heat, and static electricity. Plus, industry organizations like the American Petroleum Institute (API) promote requirements such as API 752 and 753 to promote specific requirements within the industry and hold companies to safety standards.

Many large energy companies are heavily invested in renewable energy and bring their corporate process safety standards into the renewable energy market. Safety protocols in the natural gas industry can easily be adapted to the renewable energy sector with safety protocols like site analysis, process safety management guidelines, and requirements for blast resistant buildings.

Biomass facilities convert materials like wood, waste, and agricultural residue into heat and electric power through several methods. Occupational risks at these facilities include air pollution and exposure to combustion products.

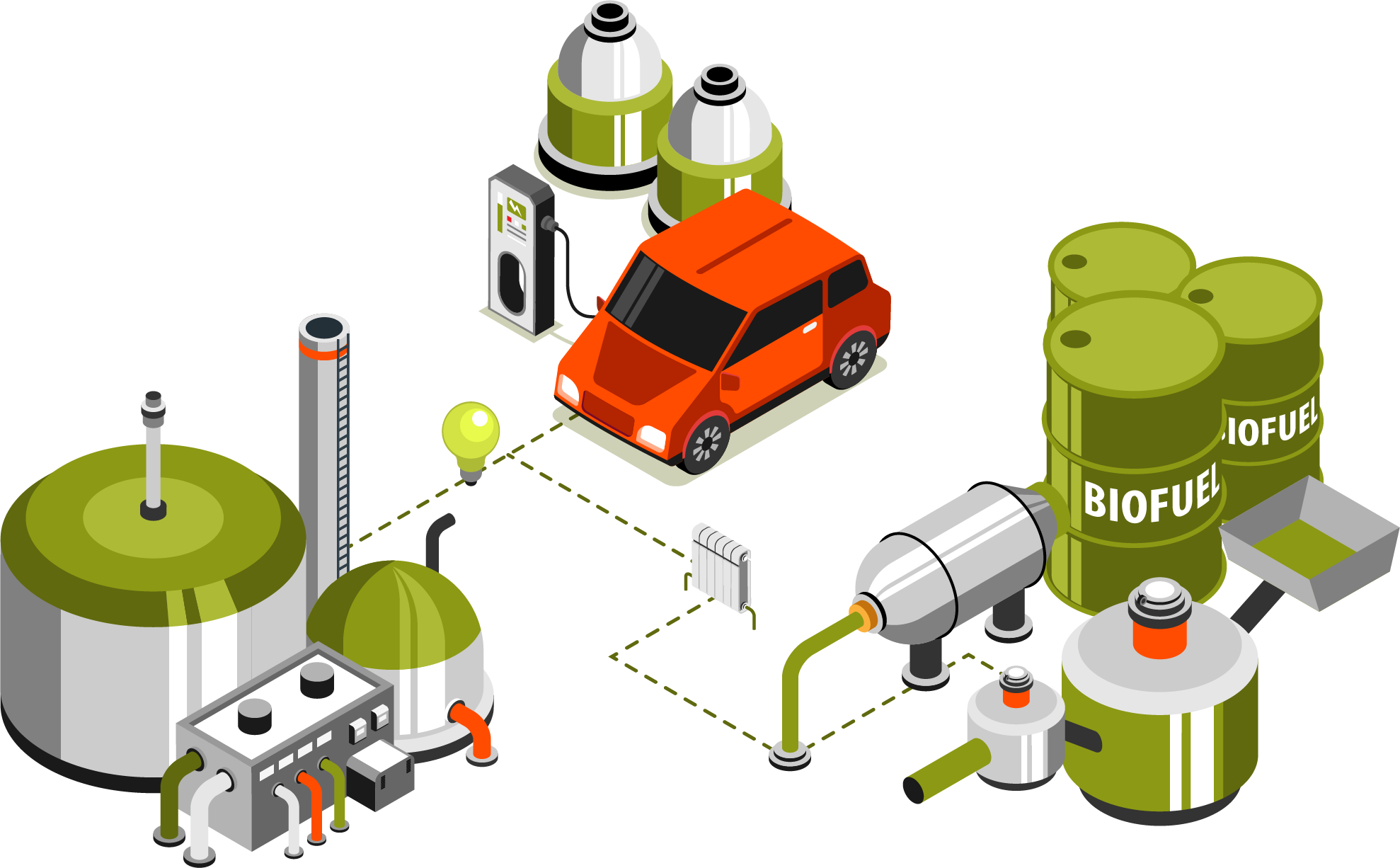

Biofuel, such as renewable diesel, is renewable, biodegradable fuel manufactured from natural waste like vegetable oils or recycled grease.

Renewable diesel meets both the biomass-based diesel and overall advanced biofuel requirements of the Energy Policy Act of 2005's Renewable Fuel Standard (which requires renewable fuel to be blended into transportation fuel). For this reason, traditional oil refineries may also have on-site renewable diesel facilities.

Blast resistant buildings are essential for workers who process, mix, and transport this fuel. Workers are most likely to need protection during the transesterification process, during which glycerin is separated, or the blending procedure, during which renewable diesel and diesel fuel are loaded into tanks for transport.

Renewable natural gas refers to upgraded biogas from municipal solid waste landfills, wastewater treatment plants, livestock farms, and food production facilities. It's used in place of fossil natural gas but needs extensive treatment to remove moisture, carbon dioxide (CO2), nitrogen, oxygen, VOCs, and other contaminants. Facilities that upgrade biogas to RNG, transport it, or inject it into distribution pipelines, must adhere to safety protocols that can warrant the use of blast resistant buildings.

Modular blast resistant buildings are especially beneficial for control room operations at processing facilities. As demand increases for RNG and new plants are constructed, they will each need new control rooms and laboratories. These buildings could be blast resistant or possibly non-blast buildings, if located outside of the blast zone. Modular blast-resistant buildings can be standardized to ensure familiarity for control operators across a company. Standardization of modular blast-resistant buildings means that the design, materials, and components used are consistent across multiple units. This consistency helps control operators become familiar with the layout and functionality of the building, regardless of the location or specific purpose of the unit. This can save time and reduce training costs since operators do not need to learn how to use different equipment or navigate varying layouts.

The rising demand for biofuel has significantly increased the number of process plants and operators who manage them. This can lead to risks involving improperly trained workers, unsuitable plant locations, inconsistency in applying guidelines, and process hazards.

Of course, when workers stay healthy, companies save money on medical and worker's compensation bills and lawsuit payments.

Biomass power plants also carry risks along with their potential environmental rewards. Those burning wood chips and pellets are particularly vulnerable to fires and explosions. For example, when a station in the UK was converted from a coal plant, it suffered a fire on a conveyor belt that cost an estimated £10 million. Fires and explosions can also release matter, such as combustible dust, into the air that leads to secondary reactions, necessitating good preparation for these accidents.

Similar to traditional industries like coal, biomass facilities face potential explosion hazards. The process of converting natural matter into power and fuel involves the use of heat, steam, and pressure, which can create volatile conditions. Additionally, biomass has the potential to off-gas when stored, further increasing the risk of explosion.

As a result, it is crucial to implement measures to mitigate these risks and ensure the safety of workers and facilities. This can include utilizing blast-resistant modular buildings that are designed to withstand explosions. These buildings can also be customized to fit the specific needs of biomass facilities and ensure that essential equipment and personnel are protected in the event of an explosion.

There have been many fires and explosions in the industry that have short durations but burn hot and have a high impact on anything in the area. Many fire and explosion causes are unknown or the result of spontaneous combustion, yet they can place the future of a facility in question. A 2013 combined-heat-and-power biomass facility in Shakopee, Minnesota, exploded, igniting a fire that burned for more than a week. It required a $7 million redesign and months of reconstruction before it was operational.

Like any other industry with inherent risks, the biomass industry benefits from better control process guidelines and installing blast-resistant buildings to protect people and property when things go wrong.

Solar technology converts sunlight into electrical energy in one of two ways: 1) via photovoltaic (PV) panels (solar electric), or 2) through mirrors or lenses to concentrate solar radiation into a receiver (solar thermal). Some solar power facilities employ a heat-transfer fluid in the receiver to produce steam, which is converted into mechanical energy in a turbine. This energy then powers a generator to produce electricity.

In solar power facilities, workers may be exposed to various hazards. If a solar company connects to the energy grid, it must abide by the safe practices in OSHA's Electric Power Generation, Transmission, and Distribution Standard, 29 CFR 1910.269.

The main risks in working with solar energy are electrocution, burns, and arc flashes, particularly when hooking up solar panels to an electric circuit. In solar power plants, high-voltage lines require close attention, primarily when workers use tools around them to conduct energy. Solar energy is typically produced in hot, harsh climates where workers also need protection.

In some solar facilities, hot water is used as a heat transfer fluid. In other facilities, a liquid beneath the mirrors is heated and then flows into a heat exchanger to boil water in a conventional steam-turbine generator. In either case, the risk of injury due to hot water or electrocution needs to be mitigated.

Solar power facilities pose primary risks of electrical hazards and falls from heights, making it essential to implement appropriate safety measures for worker and facility safety. While blast-resistant buildings may not always be necessary, it is crucial to take safety seriously.

One way to enhance safety in solar power facilities is by using energy storage buildings, such as those supplied by RedGuard. These buildings house battery arrays that store energy and regulate power generation and distribution to the grid, improving efficiency and reliability.

While windy conditions will always be a factor at wind power facilities, it is crucial to set up a facility to provide safety to all workers on-site.

Wind power facilities are often located on hilltops, mountain gaps, and open plains or water (the latter leading to an increasing number of facilities being built off-shore). Wind rotates the turbine blades (that are connected to a shaft), which turns an electric generator to produce electricity.

In 2021, 9.2% of the US's energy came from wind power. But workers at these sites also need to heed safety precautions to avoid burns, shocks, and arc fires. In 2005, a fire started as workers were heating a bolt with an oxygen-acetylene torch. Another accident involved a circuit breaker that remained energized by feedback from a transformer, causing flash burns. However, most worker injuries are a result of falls.

Non-blast storage buildings can be a suitable option for the wind power industry when it comes to storing non-critical materials and equipment. While blast-resistant modular buildings aren’t essential on wind power sites, non-critical materials and equipment can benefit from rugged storage solutions.

Non-blast storage buildings provide the necessary protection against environmental factors like wind, rain, and snow while also providing secure storage space for non-critical materials and equipment. These buildings can also be customized to fit the specific needs of the wind power industry, with features like ventilation systems, temperature control, and insulation to protect stored materials and equipment.

RedGuard's Battery Energy Storage System (BESS) buildings are an innovative solution to address the intermittency problem that affects the wind and solar industries. The challenge lies in the fact that wind and solar power production is dependent on weather patterns and is not continuous. The BESS buildings provide an efficient way to store the excess power generated during peak production periods and release it when needed.

The BESS buildings contain lithium batteries, which are known for their high energy density and can be volatile. To ensure the safety of workers and the surrounding environment, RedGuard has designed these buildings to mitigate damage.

Overall, RedGuard's BESS buildings offer a reliable solution to the intermittency problem in the solar and wind industries.

Geothermal facilities produce electricity by using steam to rotate a turbine connected to a generator. Dry steam power plants draw steam from underground wells (such as geysers), while more common flash steam power plants pull steam from geothermal reservoirs of water flow upwards and boil over into steam as the pressure decreases. In the latter case, the steam is separated from the hot water and delivered to a turbine and generator. Geothermal plants may also use binary steam if the water they are working with is under 360°F. In this case, the hot water boils an intermediary fluid with a low boiling point, which is then vaporized in a heat exchanger and used to turn a turbine.

The intermediary fluids, which sometimes contain glycol, can pose hazards to workers. Drilling at geothermal sites may also cause earthquakes or blasts of pressurized hot water, injuring people and damaging property. For example, in 1991, an accident in Guatemala City caused 33 fatalities and buried surrounding homes in stone when an explosion occurred in a borehole well that tapped into steam from a periodically active volcano. However, these types of accidents are extreme and rare.

Geothermal heating facilities use underground pipes to circulate fluid in areas where they can absorb heat. While blasts can originate in pipes, the drilling involved in building a plant can also lead to tremors and earthquakes that cause localized damage. For example, plans for a geothermal heating plant in Basel, Switzerland were abandoned around 2010 because drilling the boreholes triggered a series of tremors. But new technology and safety regulations have opened new paths toward geothermal heating plants worldwide.

Geothermal energy holds great promise for the renewable energy industry. Still, as facilities expand and multiply, there will be an ever-increasing need to protect workers from fires and blasts resulting from drilling, equipment malfunction, extreme heat, pressure, and seismic activity.

Because specialty modular buildings can be designed to withstand shock waves and heat, they can protect people and property on worksites. Custom modular buildings can also be used as mobile offices and control rooms.

Fires and explosions are not unheard of at hydropower facilities, especially when it concerns transformer issues or accidents related to facility upgrades. However, most modular buildings on these sites are used to house control rooms. While in most cases, these buildings would be rugged modular, non-blast structures, it is possible that they might be blast resistant if the siting analysis requires it.

Motor control centers (MCC) or switchgear buildings that control power at worksites and completed plants can be modular and can be provided by RedGuard.

Hydrokinetic technology allows energy companies to generate electricity from the movement of water without building dams or water diversion infrastructure. Injuries generally involve turbine-related accidents or electrocution. But in most cases, buildings on site are designed to protect equipment or are control rooms.

Non-Blast Storage Buildings can be used to store equipment at water power facilities. Any damage to control rooms or storage facilities can have precisely the environmental impact that renewable energy resources aim to avoid.

Nuclear power is increasingly being adopted as a cleaner and more efficient replacement for traditional coal and natural gas-fired power plants. The use of nuclear energy reduces greenhouse gas emissions and air pollution, making it a more sustainable option for meeting energy needs.

Nuclear power plants require strict security measures to ensure the safety of workers and the surrounding environment. This is where RedGuard's security buildings come in. RedGuard provides a range of security buildings, such as guard houses and ballistic control rooms, that are essential for nuclear facilities. These buildings are designed to protect workers and equipment from potential threats such as forced entry, ballistic damage, or explosion.

RedGuard's specialty modular buildings protect valuable human assets, equipment, storage facilities, and control gear. The advantage of steel building materials over concrete lends strength and longevity to these structures while simultaneously making them transportable and customizable.

As RedGuard looks to the future, our experts are increasingly working with renewable energy companies to ensure worker safety. And our blast-tested and third-party-engineered buildings meet and help define the industry standard for protecting people and property.

As renewable energy facilities grow and expand to new regions, it may be unclear precisely what structures will be necessary for the long term. But RedGuard’s custom construction and a pre-fabricated fleet of rental buildings can meet any need for any amount of time. Our experts can consult with site managers and contractors from the start of a worksite’s construction through upgrades mandated by new worker safety regulations.

Even when facilities need one standard design to create familiar structures around a worksite's property, RedGuard's buildings meet their needs with standard layouts. The option of standardization also allows workers to travel to worksites around the world and have a sense of familiarity with how things work. This fits in well with the process standardization necessary to scale up operations quickly to meet increasing energy needs.

RedGuard is also skilled at working with Engineering, Procurement, and Construction (EPC) firms that deliver complete packages of resources for new infrastructure projects. So no matter how broad or narrow a company’s needs are, our experts can contribute to your safety plans. Better yet, we still run collaborative designs by our engineers to ensure their integrity and add expertise on federal, state, and local safety codes and industry requirements.

Because our construction occurs off-site, renewable energy companies can keep things productive, minimize pauses for the erection of protective structures, limit their liability, protect workers from unnecessary hazards, and help companies meet tight construction deadlines.

No matter how early in the process of construction a renewable energy company is or how long they've been operating, companies all have the same goal of preserving environmental resources and protecting the health and safety of workers and their surrounding community.

Workers are most productive when their safety is taken seriously. And because so much renewable energy technology is still under development, it's just as important to have the resources available to protect workers from hazards during site construction and upgrades, as it is to have them during the energy production lifecycle. By prioritizing safety and investing in the necessary resources, renewable energy companies can protect workers and the environment and ensure the success and sustainability of their operations.

Your safety partner in threat mitigation for hazardous areas, providing safe spaces through customizable, scalable, modular buildings. The industry leader in blast-resistant buildings.